Your Cart is Empty

Description

Clear Coat

Features

Properties

Recoat Time without Sanding

Mix Ratio

Minimum Application Temperature

We make coatings that perform.

From sealing wood to fiberglassing wooden boats, System Three has perfected the protection of wood from water.

See what our technology can do for your next project.

Coatings

Product Highlights

Protect Your Furniture

Shop Clear Coat

Clear Coat is our go-to for the protection of outdoor wooden furniture, one of the toughest tasks for skilled woodworkers.

Sealing with Clear Coat and topping with a UV-protective coating is sure to keep your project safe from the elements.

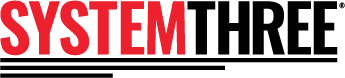

Conquer the Cold

Shop Cold Cure

Conditions can be cold, wet, or cold and wet in your shop, or outside your shop for that matter.

Cold Cure Epoxy was born in Canada over 40 years ago and continues to serve those in the harshest environments to this day.

S-1's Endless Possibilities

Shop S-1

From rotten beams to fine furniture, S-1 is as versatile as they come.

With the ability to penetrate deep into wood and a pot life measuring in hours, S-1 is ready for whatever you have in mind.

Coatings in Action

Coatings FAQ