Your Cart is Empty

Description

Mosaic

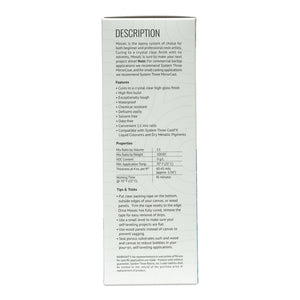

Features

Properties

Mix Ratio

Minimum Application Temperature

Full Cure

Professional quality arts and crafts resin

Create showstopping projects with Mosaic, our crystal clear Arts & Crafts resin.

Combine with our CastFX pigments and your own imagination and the sky is the limit.

Mosaic Magic

With CastFX Liquid Colorants and Dry Metallic Pigments, Mosaic can truly transform your next installation.

Formulated by artists for artists, our best in class crafting resin is sure to meet your highest expectations.

Colorants Compatible with Mosaic

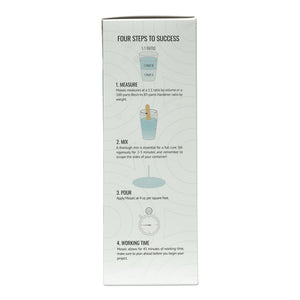

Mosaic Application Steps

Step 1: Measure and Mix

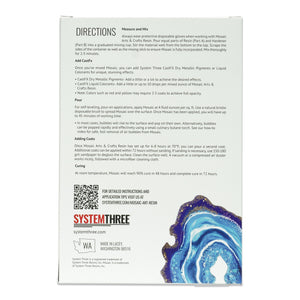

Always wear protective disposable gloves when working with Mosaic Arts & Crafts Resin. Pour equal parts of Resin (Part A) and Hardener (Part B) into a graduated mixing cup. Stir the material well from the bottom to the top. Scrape the sides of the container as well as the mixing stick to ensure Mosaic is fully incorporated. Mix thoroughly for 2-3 minutes.

Step 2: Add CastFX

Once you’ve mixed Mosaic, you can add System Three CastFX Dry Metallic Pigments or Liquid Colorants for unique, stunning effects. CastFX Dry Metallic Pigments. Add a little or a lot to achieve the desired effects. CastFX Liquid Colorants- Add a little or up to 10 drops per mixed ounce of Mosaic Arts & Crafts Resin. Note:Colors such as red and yellow may require two coats to achieve full opacity.

Step 3: Pour

For self-leveling, pour-on applications, apply Mosaic at 4 fluid ounces per sq. ft. Use a natural bristle disposable brush to spread Mosaic over the surface. Once Mosaic has been applied, you will have up to 45 minutes of working time.

In most cases, bubbles will rise to the surface and pop on their own. Alternatively, bubbles can be popped rapidly and effectively using a small culinary butane torch. See our how-to video for safe, fast removal of air bubbles from Mosaic.

Step 4: Adding Coats

Once Mosaic Arts & Crafts Resin has set up for 6-8 hours at 70°F, you can pour a second coat. Additional coats can be applied within 72 hours without sanding. If sanding is necessary, use 150-180 grit sandpaper to degloss the surface. Clean the surface well. A vacuum or a compressed air duster works nicely, followed with a microfiber cleaning cloth.

Step 5: Curing

At room temperature, Mosaic will reach 90% cure in 48 hours and complete cure in 72 hours.

Mosaic in Action

Mosaic FAQ