Your Cart is Empty

Sale

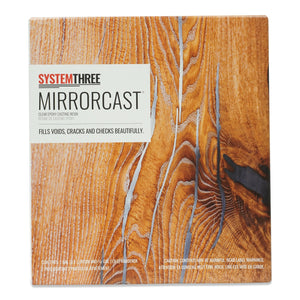

MirrorCast

$ 39.95 - $ 1,199.95$ 49.95 - $ 224.95

MirrorCast is a clear epoxy casting resin designed to fill knots, cracks and voids in wood substrates with minimal shrinkage. Use MirrorCast to fill voids prior to finishing wood components. When cured, MirrorCast can be sanded, shaped and drilled. Check out our MirrorCast Application Guideline for more details. For large voids including river tables, try RiverCast. Use with CastFX Dry Metallic Pigments or Liquid Colorants to create stunning effects!

Description

MirrorCast

Features

Properties

Working Time

Mix Ratio

Application Temperature Range

Casting Products that Perform

Countless hours and hundreds of prototype formulations helped us develop crystal clear casting resins that de-aerate better than anything on the market.

With superior clarity and hardness, coupled with zero VOCs, we believe System Three casting resins are the best you'll find.

We are here to help you Epoxy Like a Pro.

Casting Products

Casting Features

Fits all sizes

Our Casting Resins

From small voids to big rivers, System Three casting resins have been formulated to perform however your project requires.

MirrorCast for cracks, checks, and small voids. RiverCast for deep pours. We've got the right tool for the job.

Incredible Effects

Shop Pigments

Combine with our casting resins, or any of our other epoxies, System Three CastFX pigments and colorants can take your project to the next level.

Create stunning effects and make your next piece a show stopper.

Shapes Beautifully

System Three casting resins offer superior clarity and de-aerate better than the competition, but you might not know that they also shape amazingly well.

The work that we have put into formulating these best-in-class casting resins is all in the service of helping you Epoxy Like a Pro.

Casting in Action

Casting FAQ