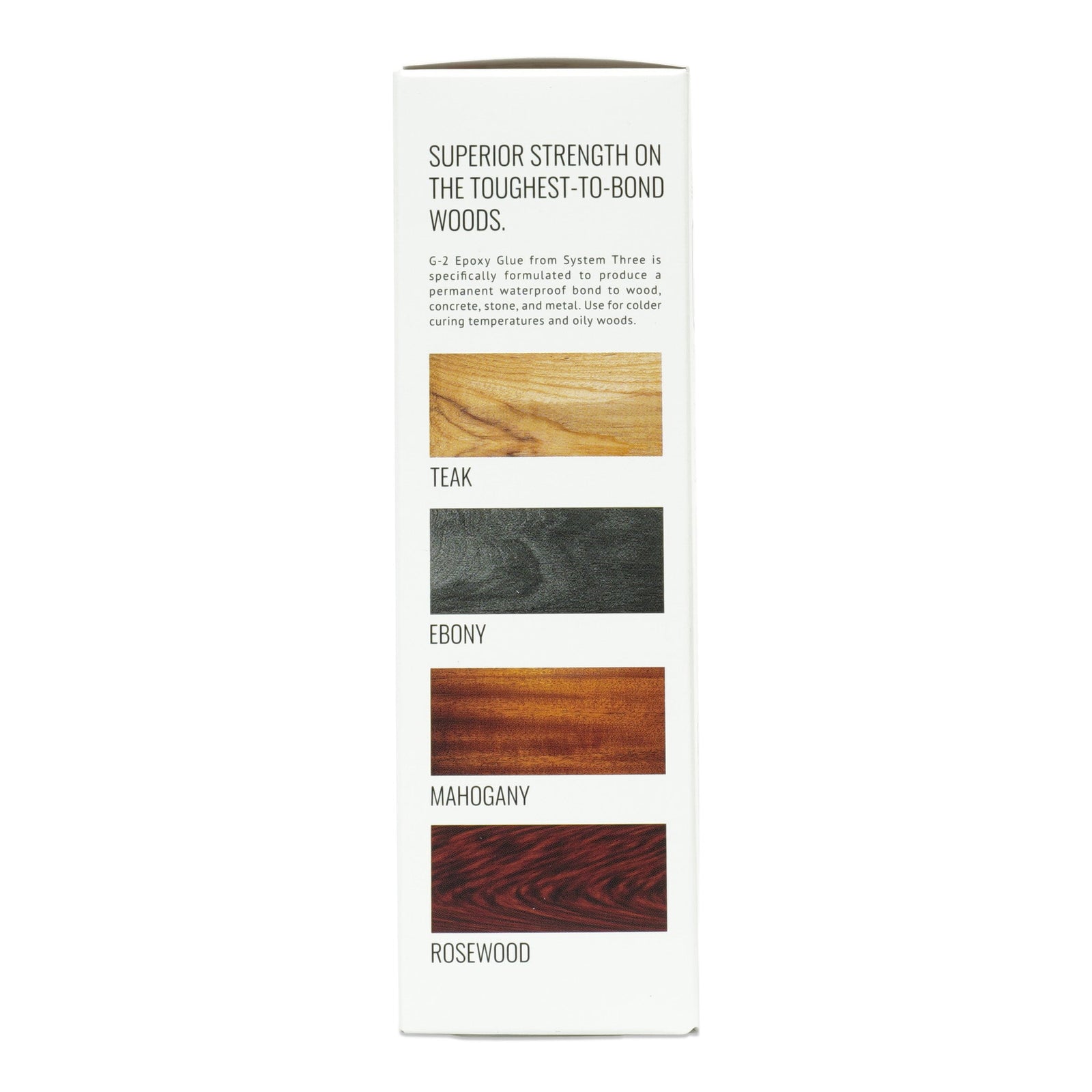

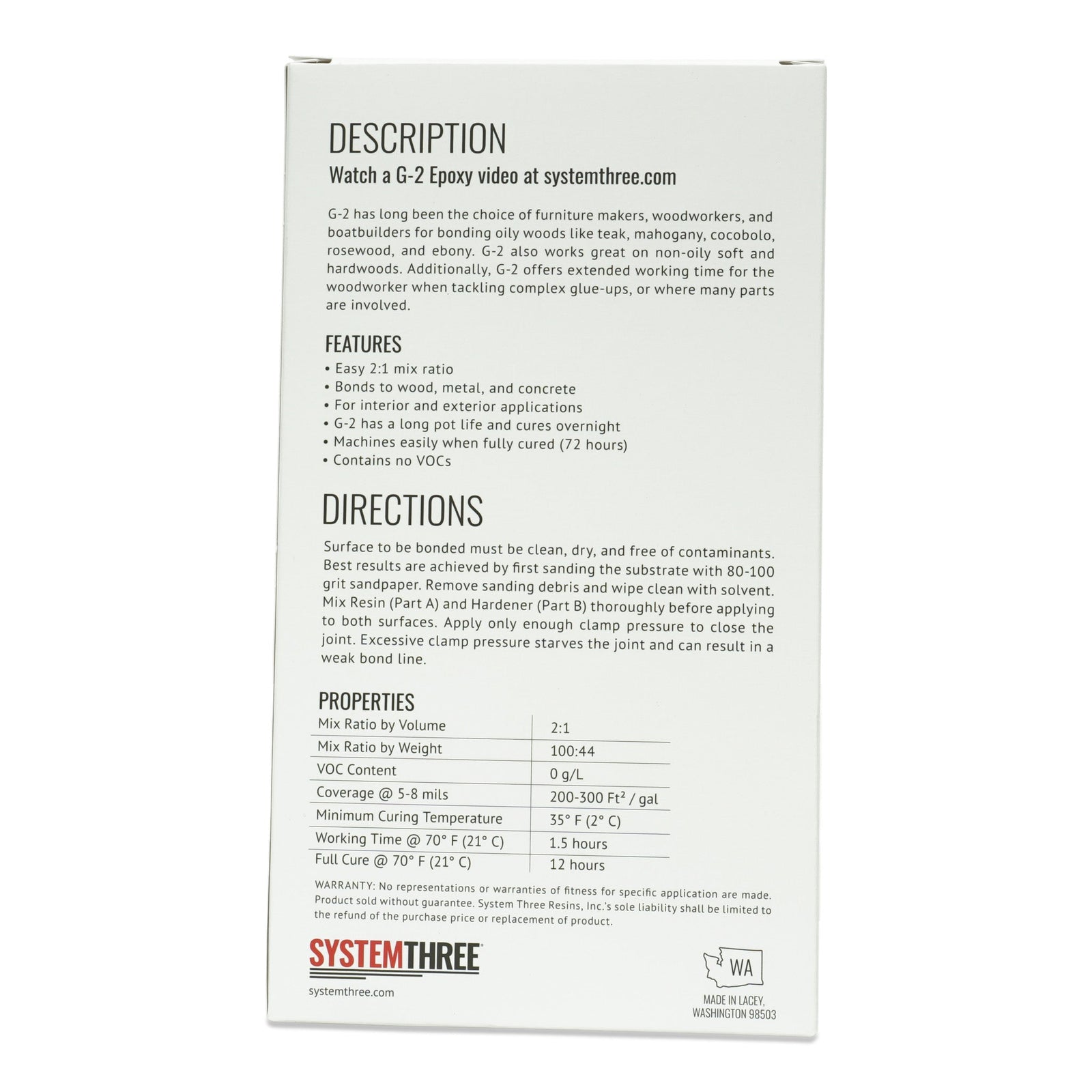

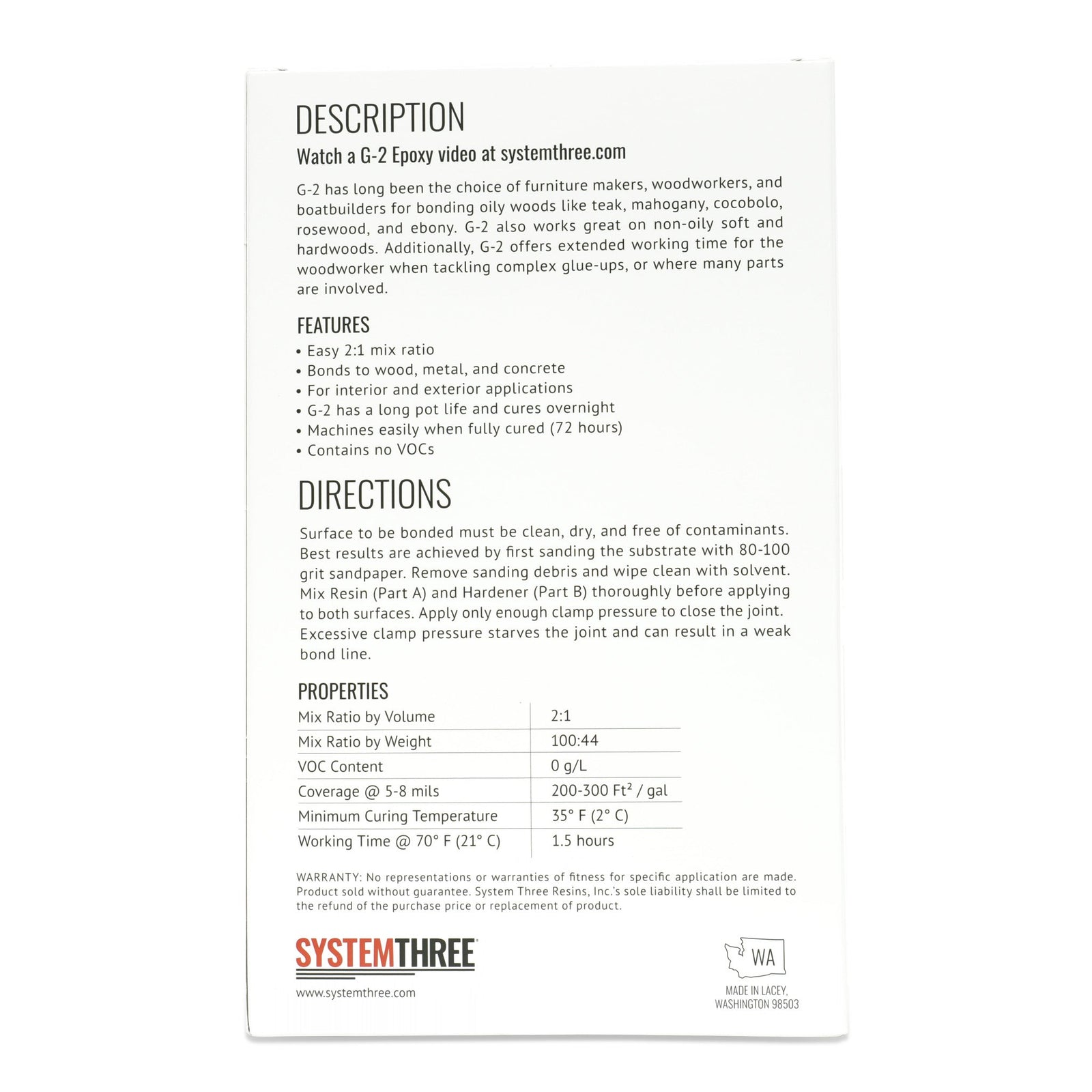

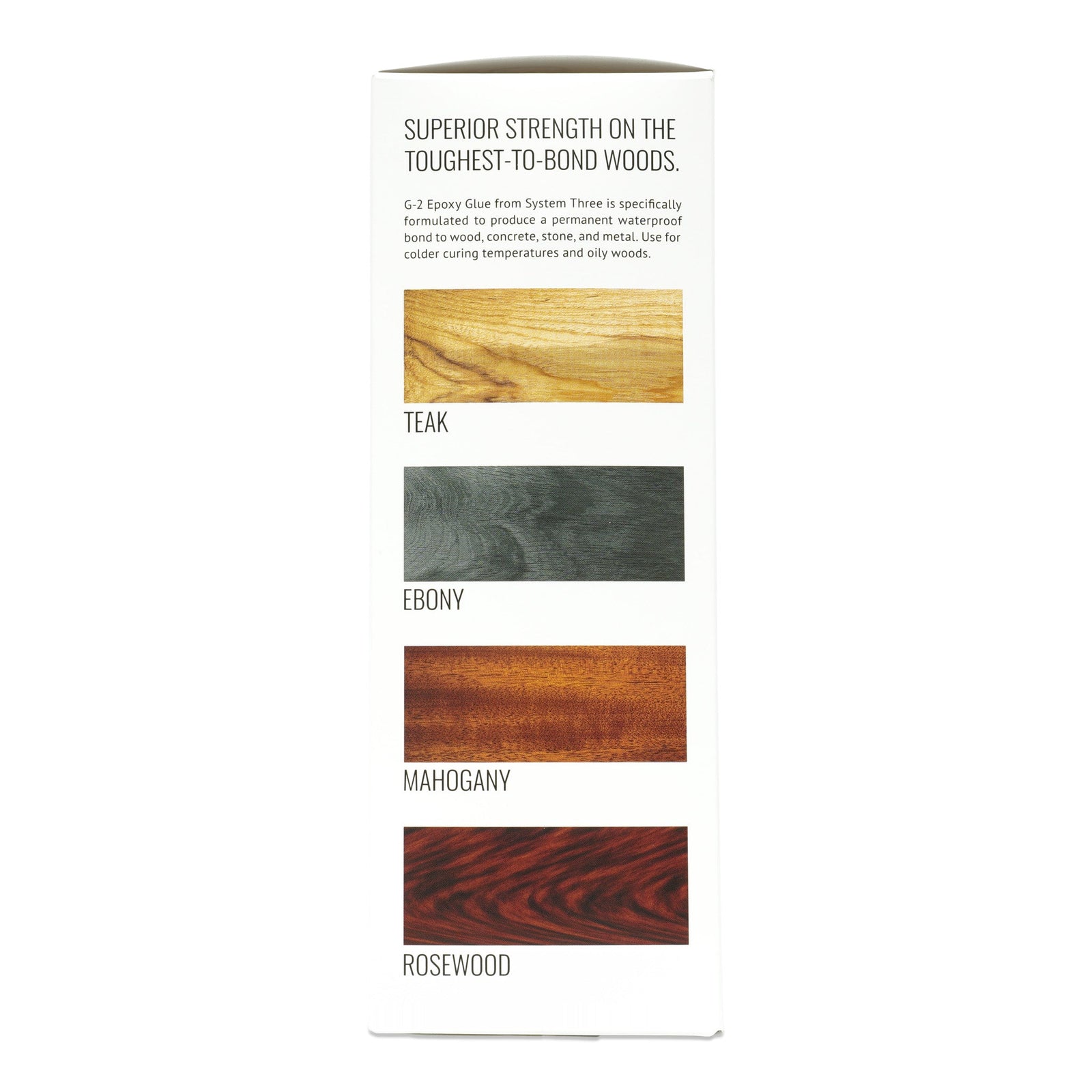

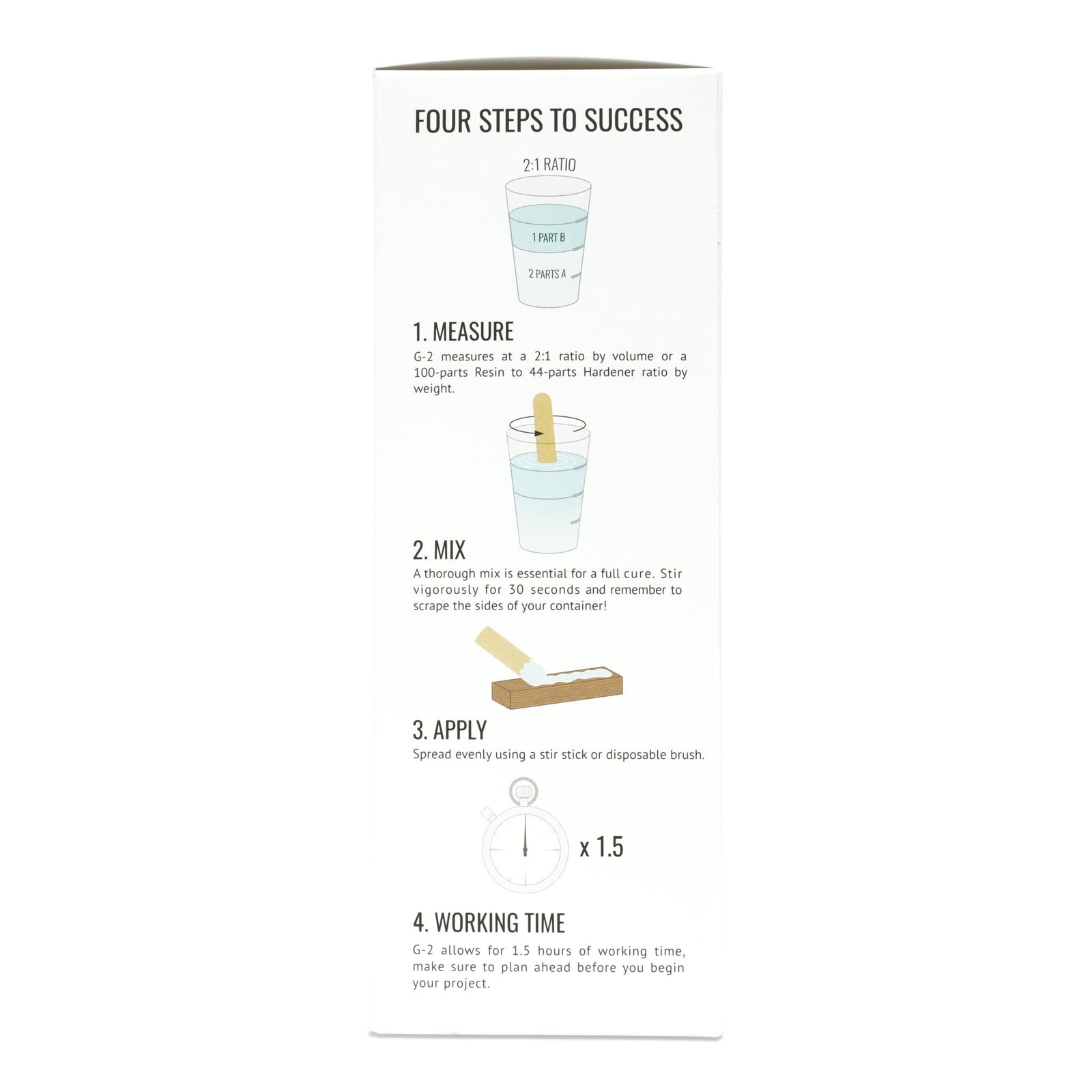

G-2 is a high-performance epoxy adhesive that excels in woodworking applications. It works well with all soft and hardwood species. G-2 performs exceptionally well with oily, tropical woods. Of particular note is G-2’s long, no-rush working time, which makes it an excellent choice for fine joinery and furniture applications.

When a strong bond is required, there is no substitute for an epoxy adhesive from System Three.

Each one of our application-specific products has been formulated with the success of your next project in mind.

With an hour of open time, G-2 is unique in the world of epoxy adhesives.

Getting clamps arranged with time to spare, plus the benefits of a structural epoxy glue? Sign us up.

We're not kidding when we describe this epoxy glue as "cutting edge." With next-generation technology enabling tenacious bonds between dissimilar materials, Blade Pro is without peer as a knifemaking adhesive.