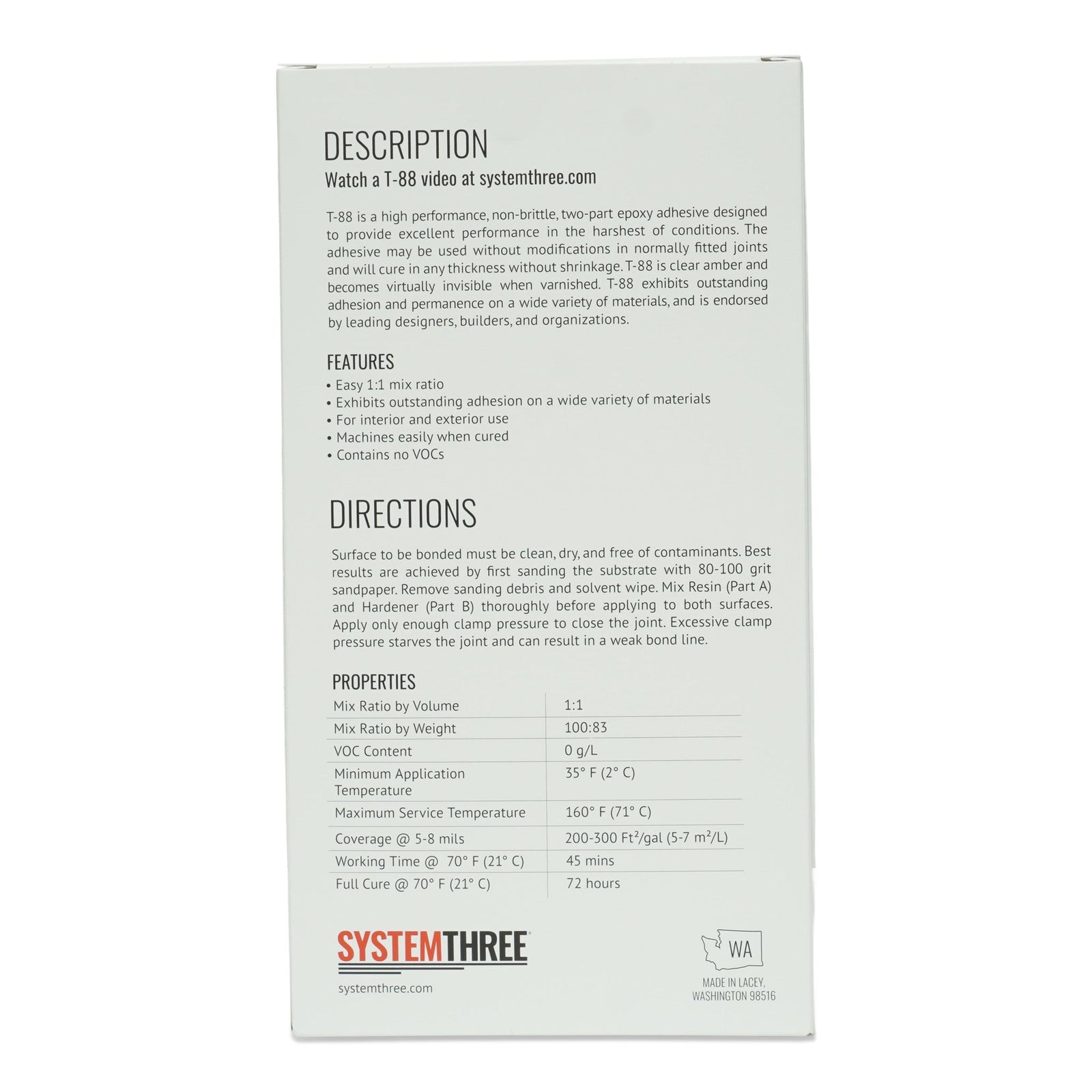

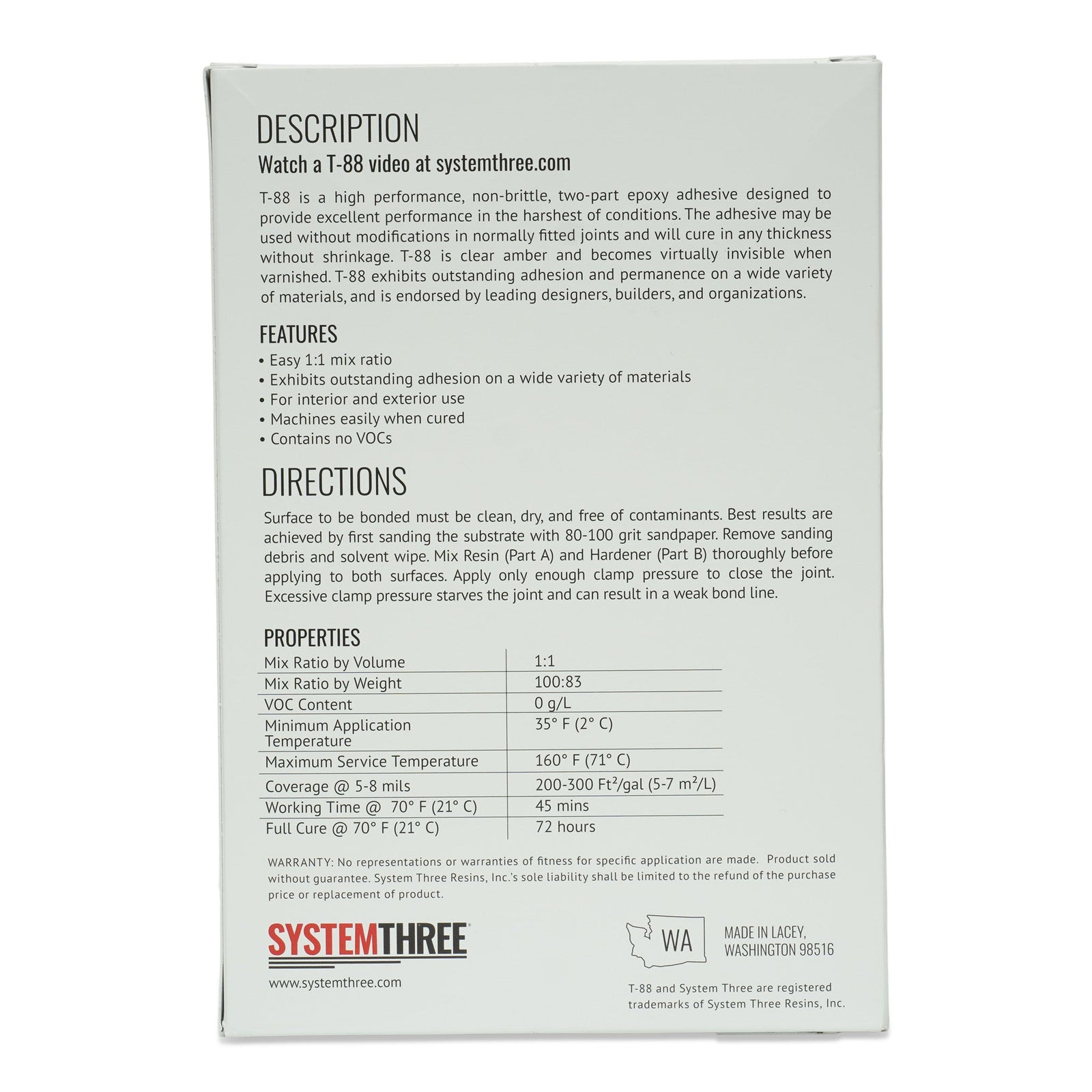

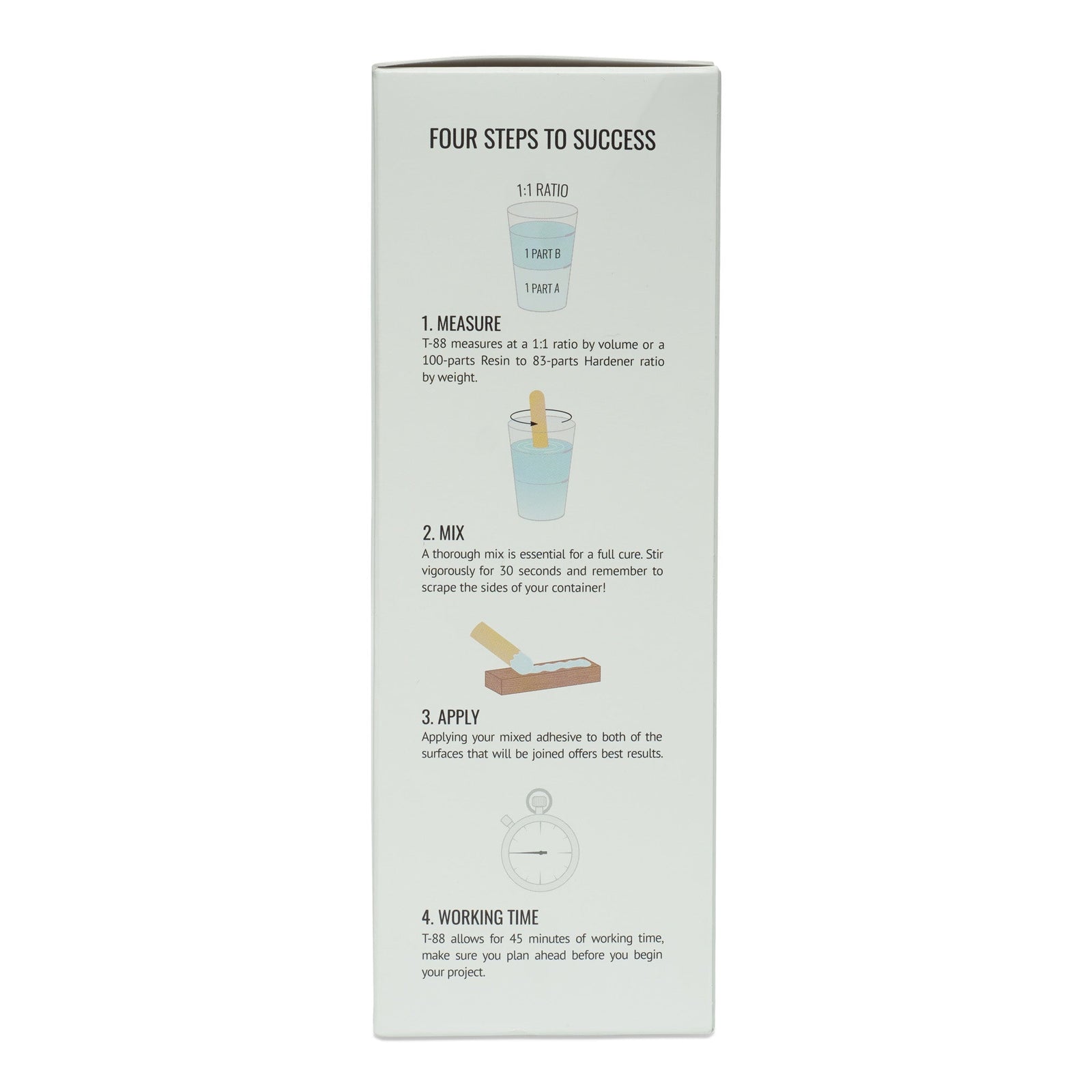

T-88 is a high-performance, non-brittle, two-part epoxy adhesive designed to give superior results under adverse conditions. The adhesive may be used without modifications in normally fitted joints, and will cure without shrinkage.

T-88 is clear amber and becomes virtually invisible when varnished. T-88 exhibits outstanding adhesion and permanence on a wide variety of materials, and is endorsed by leading designers, builders and organizations.

When a strong bond is required, there is no substitute for an epoxy adhesive from System Three.

Each one of our application-specific products has been formulated with the success of your next project in mind.

With an hour of open time, G-2 is unique in the world of epoxy adhesives.

Getting clamps arranged with time to spare, plus the benefits of a structural epoxy glue? Sign us up.

We're not kidding when we describe this epoxy glue as "cutting edge." With next-generation technology enabling tenacious bonds between dissimilar materials, Blade Pro is without peer as a knifemaking adhesive.